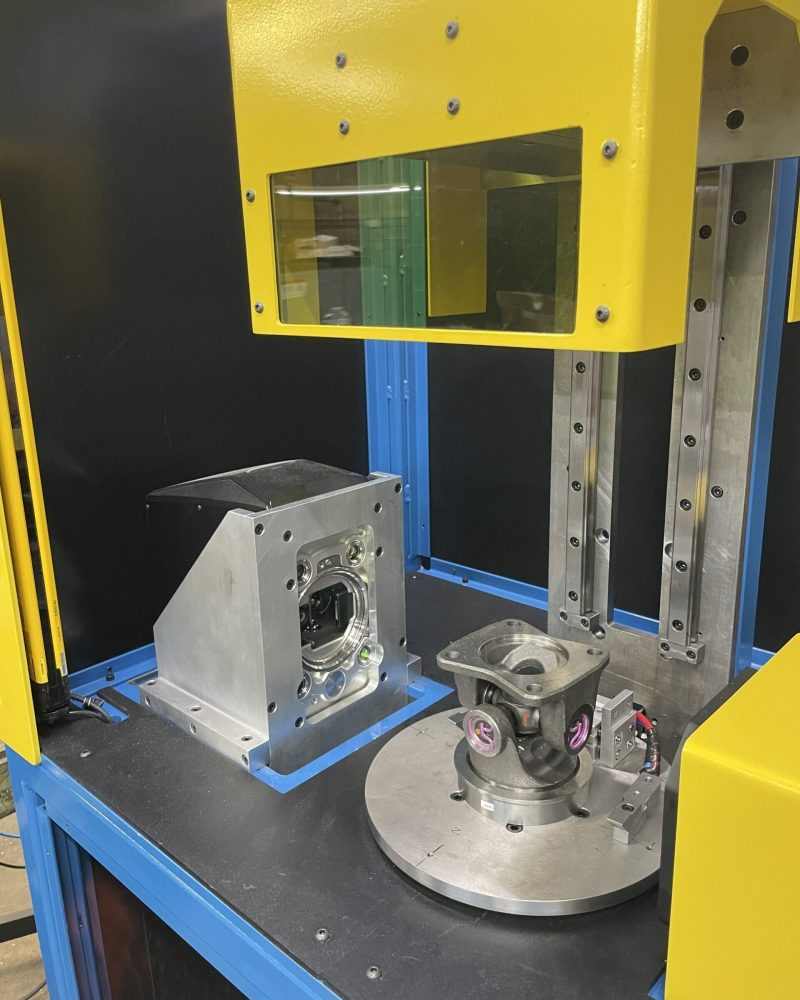

Quality Inspection Equipment

About AHE Automation

Quality Inspection

Industrial inspection and testing are pivotal for maintaining quality and safety standards on products and operations. Inspection procedures can require a standalone machine or be incorporated into existing processes.

AHE Automation designs and builds custom quality inspection equipment as part of our industrial automation services, integrating sensors, vision systems, torque validation, and presence / absence detection directly into your production line. As a custom machine builder, we create custom machines and systems around your specific parts — from weld seam inspection to lot count verification — so inspection becomes a repeatable, automated step instead of a manual check.

Examples Include:

- Quality Control (Detection of flashing, holes, fasteners, etc.)

- Presence/Absence Detection

- Paint Dot or Matrix Detection

- Lot Count Verification

- Component Placement

- Product Orientation

- Weld Seam Inspection

- Torque Spec Validation

Drive Quality Results Beyond Measure with AHE

Industrial inspection and testing demand the highest standards of excellence. Contact AHE Automation today to discuss your project with our expert team.